Waterjet machines will cut all grades of steel. It produces a smooth cut on the edge without burn marks, cracking, excess burr, or other problems typically associated with heat-based cutting or mechanical cutting. The lack of heat affected zone from the abrasivejet means that the heat treatment of the steel is not changed by the cutting process

All grades of stainless steel can be cut easily, even those Such as 304 that are difficult to machine with other processes without heat or distortion. A heat affected zone can weaken integrity of a part and lead to failure. Polished or reflective surfaces do not negatively affect the abrasivejet process as they might with a laser cutting system.

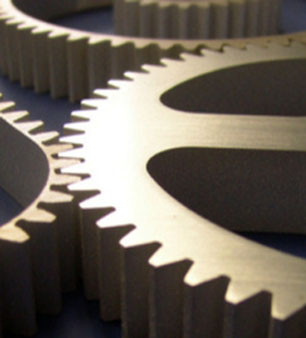

Tool steel can be cut in a fully hardened state without Any change in material properties. Waterjet cutting Offers close to EDM precision at up to 10 times the speed.

Difficult-to-machine special steel alloys, such As Inconel ® and Hastelloy ® are easy to cut without heat or distortion on our waterjet systems.

Probably more aluminum is cut on waterjet systems than any other metal because it cuts so quickly and cleanly, without any thermal distortion

Abrasive waterjet is ideal for cutting titanium, which can be a challenging material for conventional machining processes. Titanium can be cut quickly and accurately without any thermal distortion or surface embrittlement. Because titanium is so expensive, considerable cost savings can be obtained by the close nesting of parts that is possible with abrasivejet process in order to reduce waste material.

All grades of copper cut quickly and cleanly without thermal distortion. The reflectivity that may be an issue for lasers is not a problem for an abrasivejet and there is no problem with 'gumming' as might occur with conventional mechanical cutting systems.

Brass alloys cut quickly and cleanly with our abrasivejet process, with no thermal distortion.

Cutting this advanced material is a major Growth area for our system. The material Cuts very quickly and cleanly and the Abrasivejet system is now widely used in applications from aerospace components to race cars, from NASA to NASCAR.

Fiberglass can be cut quickly and cleanly Without hazardous dust or fumes by simply Submerging the material during cutting.

Any fiber-reinforced material, including Kevlar reinforced personnel armor, can be quickly and cleanly cut on our system without hazardous dust or fumes.

Abrasive waterjet is widely used for cutting a wide Variety of glass products, from ultra-thin panels for Smartphones to thick multi-layered bullet proof Panels for vehicles and buildings to panels for Stained glass windows. Our machines have the Capability to perform a low pressure pierce that Automatically switches to high pressure mode to Continue the tool path. This means that even the Most brittle glass can easily be pierced to create a Starting point and yet still be cut at maximum speed. The only glass that can't be cut is tempered glass, Designed to shatter into tiny pieces if cut or broken.

Our systems can cut stone products of All types. Applications include granite Countertops, quartz blanks for precision Mirrors, inlaid marble flooring, decorative Wall panels and stone sculptural pieces.

Concrete cuts easily with the abrasivejet Process and applications range from inlaid Stepping stones to architectural features and Sculptural panels.

Most ceramic materials can be cut with an abrasivejet. However, if the hardness of the ceramic is greater than the hardness of garnet abrasive (between 7.5 and 8.5 on the Mohs scale), abrasivejet cutting will not be economically effective

Softer rubber and foam rubber cut easily using a water only nozzle without abrasive. Fiber re-inforced fubber and very hard rubber can be cut cleanly using the abrasivejet process.